Guide to Utilize 3D Printing to Create a Prototype

3D printing a utilitarian model is one of the most basic strides in the advancement of any item or arrangement. It takes into consideration testing, active put-togetherness testing, and the capacity to make a plan emphasess on the fly before the end result is made. It considers issues and deformities to be found rapidly, saving you both time and cash. Additionally, prototyping should be possible in 5 simple tasks.

There are various added substance fabricating advances you can utilize contingent upon the kind of model you need to make. For motivations behind this article, we will zero in on Fused Deposition Modeling (FDM) innovation since that is the normal innovation utilized for work over authenticity.

3D printing is one assembling strategy that has progressively developed to carry changes to the business. That is the reason a great many people are starting to embrace 3D prototyping in light of the fact that it’s reasonable, and has a phenomenal sort of adaptability.

Since its starting to acquire some degree of consideration, 3D printing is relied upon to be completely taken on by many individuals I’m various ventures soon. Have you at any point pondered with regards to the various uses of 3D imprinting on models? Then, at that point, adhere to this aide; you will observe top ways that you can make a model with 3D printing.

As expressed in the presentation, having the option to quickly model is the best benefit of cutting-edge 3D printing. For my team(Wavy), most of our parts would need to be uniquely arranged and specially created. When on a tight time plan where there may just be half a month to convey an item, this is certifiably not an attainable arrangement; it might require fourteen days only for the part to show up at your entryway. This turns out to be considerably clearer while acknowledging how little chance there is for emphasis.

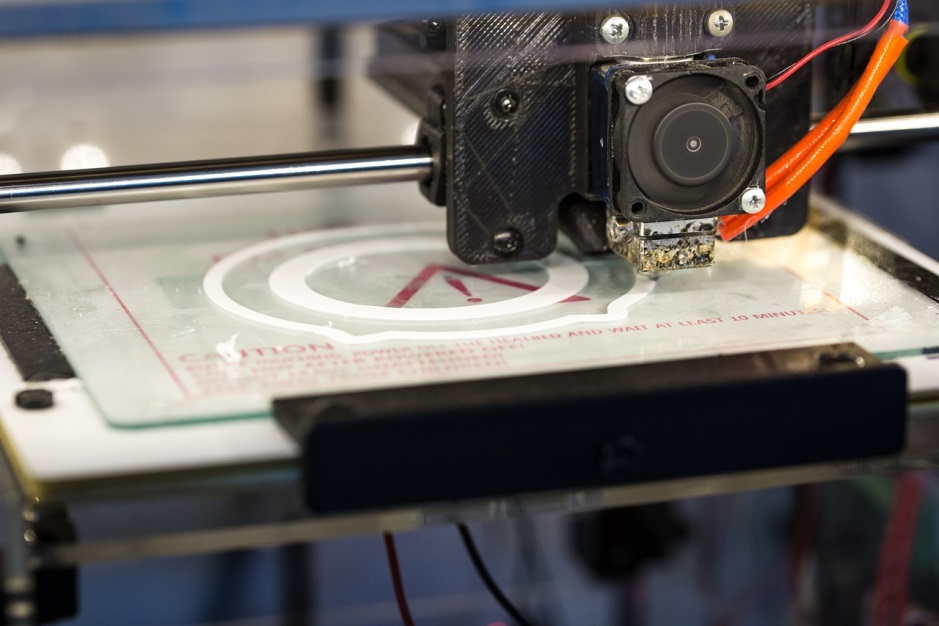

While it is surely not feasible, working under the supposition that it would require 1 or 2 weeks only for a solitary cycle makes rethinking parts would not work with regards to this class. Notwithstanding, when utilizing a 3D printer, we had the option to create different cycles each day. Further, quickly prototyping through a 3D printer not just allowed us to change plans on a full scale, yet additionally on a better miniature size. As seen underneath, we had the option to roll out a lot more modest improvements effectively as it would just cost us a couple of hours, rather than days.

How 3D scanners are used to collect data?

Specialist engineers also use 3D scanners to reverse engineer parts and components that can then be 3D printed.

What is 3d Printing?

In straightforward terms, 3D printing utilizes a cycle known as added substance fabricating. It permits individuals to make complex parts and items layer by layer utilizing a 3D displaying programming program. 3D printing permits anybody, including organizations and purchasers, to make anything for a portion of the expense and time it would ordinarily take.

A portion of the items that can be made are toys, prosthetic appendages, plane parts, and that’s only the tip of the iceberg. Allow your creative mind to go out of control!

The innovation took into account the relieving of photosensitive gum layer by layer making an article or part. He got the patent in 1986 and set up his organization 3D Systems. In 1987, the organization delivered its first item, the SLA-1. Frame sent off 3D printing into the innovation business, and his organization is presently one of the biggest 3D printing organizations.

Working on 3d Printing?

3D printing all beginnings with making or downloading a computerized model. The model can be made utilizing a 3D scanner, demonstrating programming, or application.

When the model is finished, cutting programming is utilized to partition the model into large number of level layers.

Later this, you transfer the computerized STL or VRML record to the printer. The 3D printer deals with the rest by making the article. Contingent upon what is being made, the interaction can require hours to days.

What Materials Are Needed For 3D Printing?

- Demonstrating Software

To make an advanced 3D record, you will require demonstrating programming. There are various choices accessible shifting in cost and ease of use. For amateurs, Tinkercad and FreeCAD are suggested.

- 3D Scanner App

To make your own model, you might pick a 3D examining application. These applications empower clients to make 3D models of any item. For instance, a jar or cup that you truly like. Be that as it may, the models made for the most part require some altering prior to sending them to be printed. The best 3D scanner applications to attempt are Trnio, Qlone, and Scandy Pro.

- Grafting Software

This product makes slim flat layers of a computerized 3D model. This is important to appropriately deliver and print a 3D article. For fledglings, Cura, 3D Printer OS, and KISSlicer are incredible choices.

- 3D Printer

The 3D printer you choose to get relies upon what you intend to involve it for. Is it for business or individual use? What is your spending plan for the machine and other printing material? Would you like to make hued objects? These are the issues that need replying prior to settling on your official conclusion.