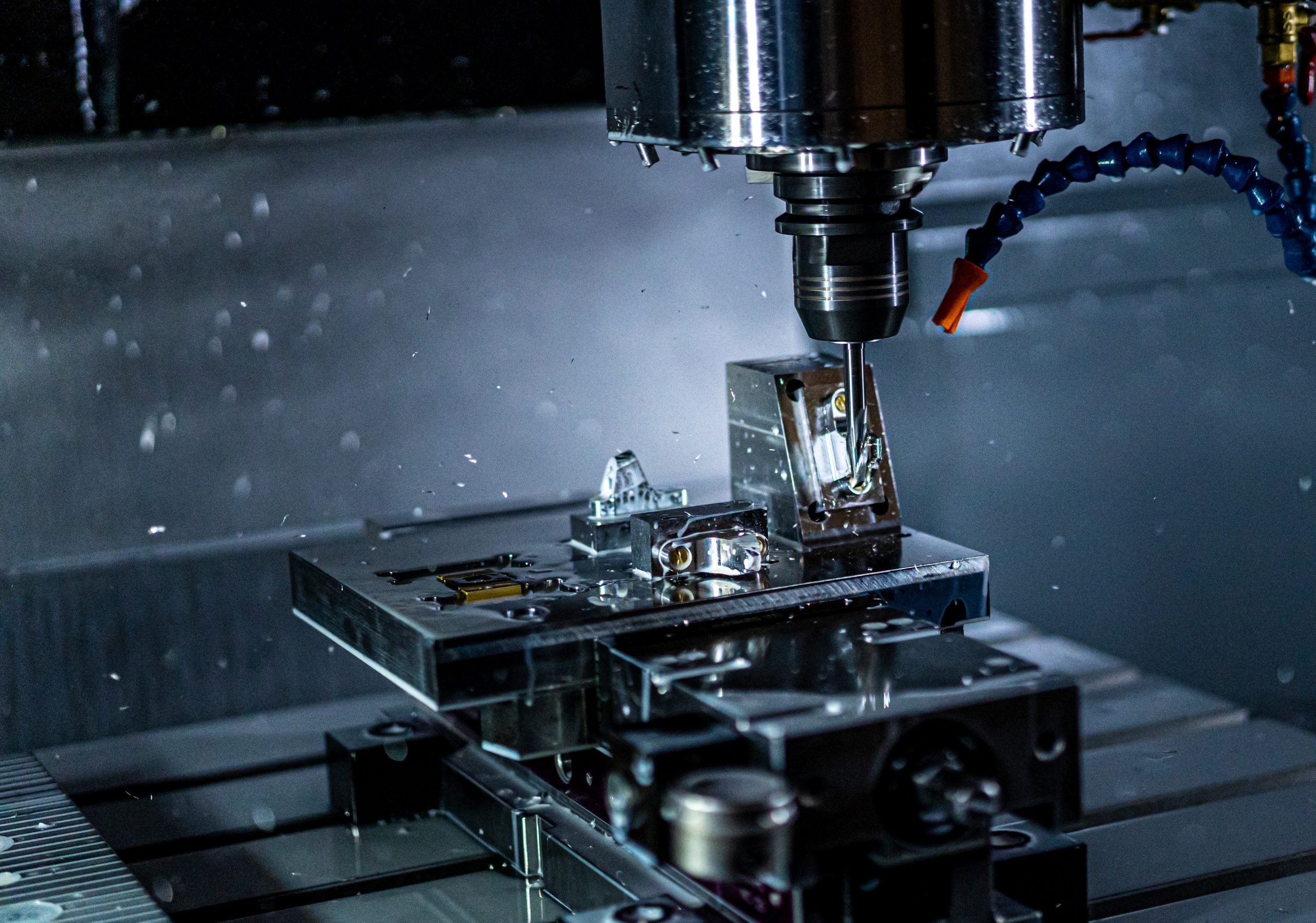

How Outsourcing CNC Machining Projects Grow Your Business

Whether you run a small manufacturing business or planning to start one, managing production is among the most challenging jobs. It’s essential to keep the operational cost low and retain constant profitability to stay relevant. One of the main ways companies can achieve this is by outsourcing their CNC machining projects.

By outsourcing CNC machining work to a trusted third-party company, business owners save cost & time and ensure higher productivity. Instead of integrating an in-house CNC machining setup, below are the cutting-edge advantages that companies can embrace:

Access To Skilled Talent

The most significant advantage of opting for outsourced CNC machining services is instant access to industry professionals. In addition, when you outsource, you can be sure of excellent quality, accuracy, and timely delivery. As not everyone is capable of delivering the desired finishing and quality, you need. So, it’s always a smart move to opt for a professional CNC outsourcing company.

The professionals understand complex design and ensure maintaining exact dimensions, suitable materials for your project. When you hire skilled professionals, they can take care of all your project aspects, including designing, production, and post-processing.

Superior Quality Control

When you manufacture parts using the CNC machining process, they must be of excellent quality and accuracy. For achieving it, you need to have a continuous quality control check that consumes substantial time. So, it’s ideal to outsource the CNC operations and let professionals have excellent quality control over your project.

Quality control can start becoming a significant issue over time, and you might end up providing sub-par quality products to your customers. When working with a CNC outsourcing partner, you can ensure the products are accurate and functional as needed by customers. As the company will use the latest CNC machines to manufacture products, you don’t need to worry about quality.

No Additional Cost

When you outsource CNC work to a professional company, you save substantial money as you only need to pay for the service. Setting up an in-house CNC machine is expensive, and you might not be able to utilize it to its maximum potential. Also, there is an additional expense of hiring experts or training your team members to operate the CNC machine.

Photo by Daniel Smyth on Unsplash

The majority of the company don’t need a steady production using CNC, and that’s why it’s convenient to outsource the entire project. And, the best part is that the cost of CNC machining materials is also included in the service, and you will get in under the same roof.

Similar to any setup, CNC machines also require regular maintenance, and you can’t overlook it to ensure robust performance. You can eliminate this cost as well by opting for an outsourcing partner.

Robust Support

You get rapid manufacturing and designing support for your project, making the entire development cycle seamless. On the contrary, if you create a part in-house and it doesn’t fit the system you needed, you have to figure it out on your own. It’s not the case when you work with outsourcing partners as they always deliver the best products.

If your product needs particular design improvisation, the designers can do it in a shorter turnaround time and speed up the manufacturing. On the other hand, if you don’t have an in-house designing expert, you need to search for a solution to fix the design and then manufacture it.

Faster Delivery

You can expect faster deliveries of your projects as the professionals work full-time and they’re trained to complete the job with perfection as fast as possible.

If you need your CNC parts more quickly to speed up your business, you should hire a CNC outsourcing company to get it done. Many companies deliver products globally with shorter lead times, so you don’t have to wait for a longer time to get your products.

Final Thoughts

CNC machining outsourcing makes sense for your business as it gives you speed, flexibility, and cost-efficiency. In addition, as skilled professionals will work on your project, you don’t have to worry about the quality.