What Can Thin Film Deposition Do? Exploring its Diverse Applications

The art and science of thin film deposition are technical and highly influential. The capacity to deposit exceedingly thin layers of material onto a surface brings up many new opportunities in various industries. These thin films, which are sometimes only a few nanometers thick, can significantly alter the properties of a material, enabling previously imagined behaviours and capabilities.

In this blog, let’s find out the other applications of thin film deposition, painting a comprehensive picture of its ubiquity and versatility.

A Deeper Dive into Thin Film Deposition

Before we get into the uses of thin film deposition, let’s review what it is. The act of depositing layers of material — the ‘thin films’ — onto a surface, also known as the substrate, is known as thin film deposition. Depending on the deposition procedure and the desired result, the thickness of these layers can range from a few atoms to several micrometres.

Let us now delve into the plethora of its uses!

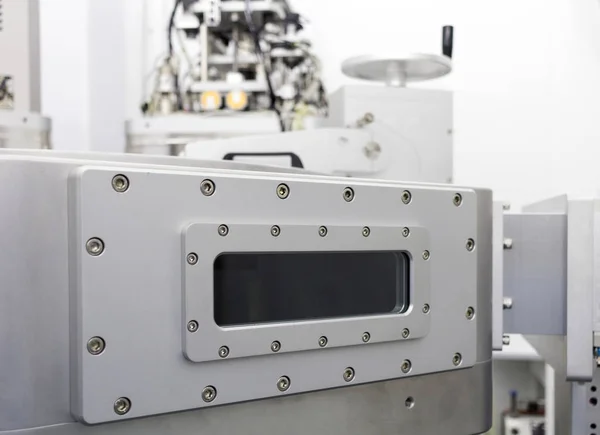

Boosting Efficiency: The Impact In The Electronics Industry

Thin film deposition has transformed the electronics industry by allowing smaller, more powerful electronic devices to be manufactured. Semiconductor devices, such as those found in smartphones and laptop computers, rely significantly on thin films to work. Thin films serve as the conducting and insulating layers in integrated circuits, allowing for precise control of electric currents and enabling these devices’ complicated activities. Thin film deposition is also essential in developing micro-electro-mechanical systems (MEMS), which are tiny mechanical components integrated into inkjet printers and airbag systems. These micro-devices require the exact deposition of thin coatings to accomplish the desired functionality.

Illuminating the World: Optoelectronics and Photonics

Thin film deposition is critical in the production of gadgets that illuminate our lives in the field of optoelectronics and photonics. Thin films are used extensively in lasers, light-emitting diodes (LEDs), and solar cells. Thin films, for example, play an important role in creating LEDs, which are widely utilised for energy-efficient lighting solutions. LEDs can produce a broad spectrum of colours because of the thin film deposition processes used to deposit the various layers. Furthermore, thin films are used in solar panels, which harness the sun’s power to generate electricity. These thin film coatings on solar cells contribute to the developing field of sustainable energy by converting sunlight into electrical energy via the photovoltaic effect.

Enhancing Protection: Automotive, Aerospace, and Consumer Goods

Thin films provide increased protection to various materials, improving durability, resistance, and aesthetic appeal. Thin film deposition is used to develop coatings that improve wear resistance and minimise friction in industries such as automotive and aerospace, where surfaces are subjected to rigorous conditions. These coatings can extend component life, reduce maintenance costs, and improve performance. Thin film deposition techniques are used in the jewellery and consumer goods industries to generate attractive and durable coatings that will enhance the appearance and lifespan of items.

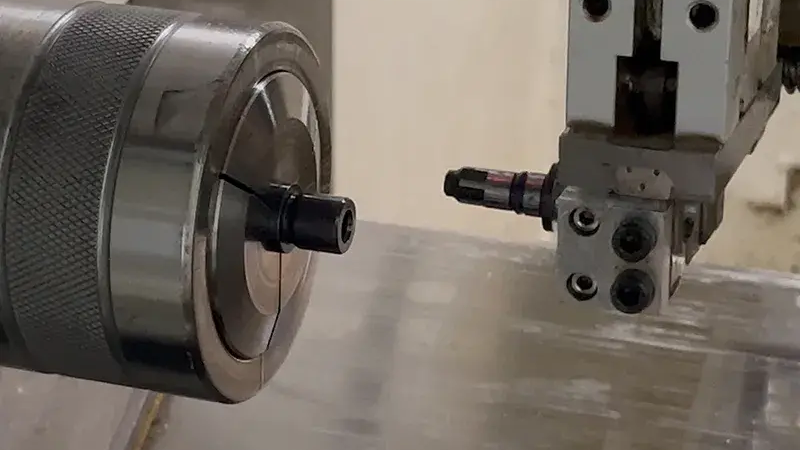

Advancing Microscopy: Thin Film Coatings for Electron Microscopy

Thin film deposition has been critical in advancing microscopy techniques, notably electron microscopy. The conductivity of the sample surface is enhanced by putting thin film coatings on it, decreasing charging effects and improving image quality. These coatings enable scientists and researchers to see samples with greater clarity and detail, allowing them to advance in materials science, biology, and nanotechnology. Electron microscopy has been transformed into a powerful tool for understanding the microscopic world thanks to thin film deposition.

Pushing Boundaries in Healthcare: Biomedical Implants and Drug Delivery Systems

Thin film deposition technologies have several uses in medical devices in healthcare. Thin film coatings increase biocompatibility and minimise wear in biomedical implants such as joint replacements and dental implants. These coatings can increase device lifetime and patient outcomes by promoting greater integration with bodily tissues. Thin film deposition is also used to create drug delivery systems, where coatings are intended to release medication in a regulated manner, assuring targeted therapy while reducing negative effects. Thin film coatings are also crucial in biosensors, allowing for sensitive and selective detection of biological molecules for diagnostic and monitoring purposes.

Going Beyond the Surface: Thin Films in Packaging

Thin film deposition has found unexpected uses in packaging, particularly in the food business. Thin films can limit gas permeability in food packaging materials, preventing gas exchange between the package and the environment. This helps perishable food last longer by retaining freshness and preventing spoiling. Thin films operate as barriers against oxygen, moisture, and other environmental elements that can compromise food quality, ensuring that consumers obtain items that have the best taste, texture, and nutritional content.

What Are The Prospects For Thin Film Deposition?

With continual breakthroughs in deposition processes and the development of innovative materials, the prospects for thin film deposition look bright. Researchers are working to improve control parameters, improve uniformity, and reduce process costs, allowing for more efficient and precise thin-film production. The discovery of novel materials with distinct features, such as improved semiconductors and hybrid materials, will open up new avenues for application in various industries.

Furthermore, combining thin film deposition with new technologies such as nanotechnology and 2D materials has enormous potential for developing high-performance devices, flexible electronics, and susceptible sensors. Future improvements will also focus on reducing energy use and developing ecologically friendly alternatives, making thin film deposition more sustainable in the long run as sustainability becomes a priority. Overall, the future of thin film deposition promises to usher in novel breakthroughs and transformative applications in various sectors.

Thin Film Deposition: The Invisible Game Changer

Thin film deposition discreetly improves the world around us, from the electronic device in your hand to the solar panel on your roof, from the automobile you drive to the packaged food you consume. Its applications are extensive, demonstrating the adaptability of this strong technology.

The need for adaptive, efficient, and precise technology has never been greater in a quickly changing world. Thin films – and the inventive deposition procedures used to make them – will play an important role in shaping our future as we continue to push the boundaries of science and technology.

Thin film deposition applications will only grow as technology advances, stressing the significance of understanding and leveraging this remarkable technology. So, the next time you pick up your smartphone or put on a piece of jewellery, remember there’s more to it than meets the eye, thanks to the magic of thin film deposition!