Choosing the Right Casters for Your Application

Introduction

Enhancing mobility in equipment—whether industrial machinery, medical devices, or office furniture—relies on selecting the right casters for your specific needs. The process isn’t about picking wheels but finding the ideal match to ensure optimal performance, durability, and safety. Whether you’re retrofitting existing equipment or customizing new projects, understanding how to selectwheels for cartsis foundational to designing effective solutions for your workplace or facility.

Applications differ widely, and so does the choice of casters. Selecting the correct type and material not only guards against unnecessary wear and tear but can enhance operational efficiency and reduce maintenance costs in the long term. Understanding caster fundamentals also helps prevent floor damage and fosters a safer working environment.

Understanding Caster Types

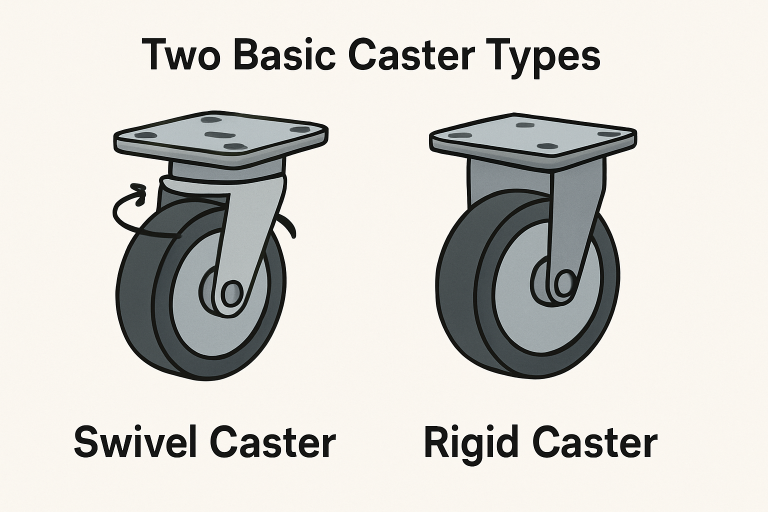

Casters are designed in : swivel and rigid. Recognizing how they function and where they excel sets the stage for further customization.

- Swivel Casters:These offer 360-degree rotation, making them an essential choice for applications where frequent directional changes are necessary, like in hospital beds, rolling tool chests, or restaurant carts, where nimble navigation is critical.

- Rigid Casters:Built to move in only one direction, rigid casters are best for applications that need straight-line stability, such as conveyor equipment or heavy-duty racks that are seldom repositioned.

For many projects, combining both types—swivel on one end, rigid on the other—delivers a blend of maneuverability and stability, accommodating a wide range of operational needs.

Key Factors in Caster Selection

Selecting castersisn’t only about mobility. Some critical elements require careful assessment:

- Load Capacity:Underestimating the weight your equipment needs to support can lead to caster failure, equipment damage, or safety hazards. Always match or exceed the weight guidelines provided by the caster manufacturer.

- Flooring Type:Match the wheel’s composition to your flooring to minimize surface damage. For example, soft wheels are ideal for hardwood, while harder wheels fare better on carpet or concrete.

- Environmental Conditions:Exposure to water, chemical agents, or high heat may necessitate special materials. Neglecting this consideration can lead to corrosion or accelerated wear.

Carefully weighing these factors before purchase ensures that the selected caster will be functional and safe in its environment. For a deeper dive into how workplace equipment can impact safety and productivity, visit this comprehensive overview by Industrial Magazine.

Material Considerations

Material choice influences everything from load rating to the type of maintenance required. Here are the most common options:

- Polyurethane Wheels:Polyurethane is often considered the go-to for multipurpose use. It combines resilience with floor protection, and its resistance to abrasion and chemicals makes it valuable in warehouses and healthcare settings.

- Rubber Wheels:Noted for their quiet, cushioned ride, rubber wheels shine in office environments or on delicate floors but may degrade faster under constant heavy loads.

- Metal Wheels:The ultimate workhorse, metal wheels can bear extreme weights and withstand rough usage. However, they are noisier and can damage floors without proper preparation.

Considering the likely environment in terms of traffic, noise tolerance, and floor quality will help you choose the optimal material for your casters.

Load Capacity and Durability

Load capacity isn’t just the sum of what a single caster can handle; divide the equipment weight (including its contents) across the number of casters, then add a safety factor to allow for uneven weight distribution and shock loads. Overloading casters results in deformation, braking failure, and can present an immediate hazard in busy environments.

Manufacturers provide clear load ratings. Ignoring these guidelines is a primary cause of premature caster failure. Ensure every component is up to the task, especially if mobility is vital for your application’s productivity or safety.

Environmental Factors

The operational setting significantly impacts caster longevity and function. Consider these environmental elements:

- Temperature Extremes:Plastic and rubber compounds may become brittle and lose performance at very low temperatures, while high heat can degrade specific polymers and lubricants.

- Exposure to Chemicals:Industrial cleaning agents, oils, and solvents can rapidly degrade unsuitable wheel materials, leading to splitting or losing traction.

- Moisture Levels:High humidity or frequent water exposure demands corrosion-resistant designs—stainless steel or specialized coatings are preferable in these scenarios.

Factoring in the daily environment ensures longevity and optimal ROI from your caster investment. Machine Design also provides guidance on selecting industrial hardware for challenging environments.

Maintenance and Safety

Routine inspection and maintenance are non-negotiable for any equipment with casters. Schedule regular checks according to the manufacturer’s recommendations. Focus on:

- Checking wheels and axles for wear or cracks.

- Removing any debris or buildup from wheel treads.

- Lubricating bearings and swivels to maintain silent, smooth operation.

Sticking to a proactive maintenance routine extends service life and helps mitigate workplace accidents caused by faulty mobility equipment.

Conclusion

Choosing the correct casters means looking beyond basic functionality to evaluate load capacity, material construction, and the operational environment. Given the array of available options, an informed selection empowers your equipment to deliver optimal utility, protecting your floors, staff, and investment. For more guidance or to shop for quality solutions, explore wheels for carts designed for various commercial and industrial needs.