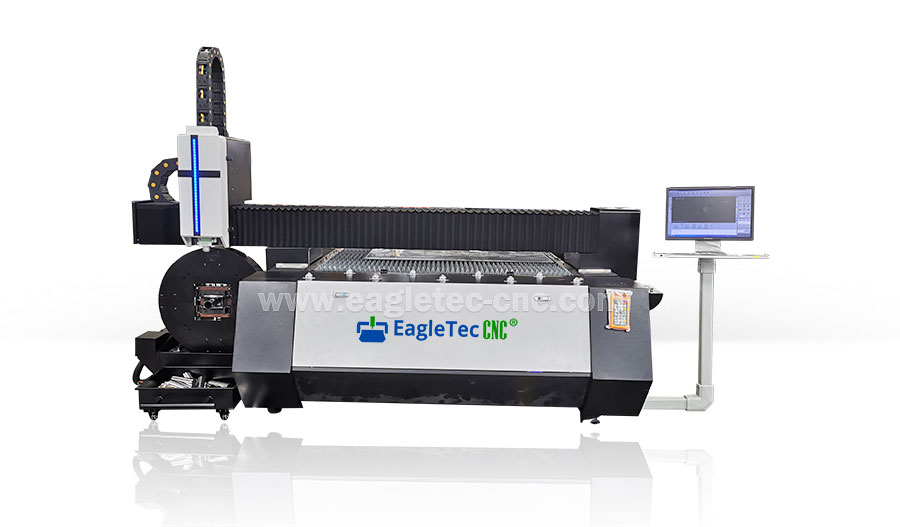

Where Can I Buy a Fiber Laser Cutting Machine of Great Quality

What is a fiber laser cutting machine?

A fiber laser cutting machine is a machine used to cut metal using a laser beam. Through the exterior control system, a laser metal cutting machine concentrates the green laser output from the laser generator on the laser beam illumination state of high operating voltage. The resulting material absorbs the laser light, and the temperature of the object rapidly rises.

How many types of fiber laser cutting machines are there?

EagleTec CNC Company, the best machine manufacturer, has four types of metal laser cutting machines. The metal plate laser cutting machine, the laser tube cutter, the fiber laser with the side tube cutter machine, and the precise small metal laser cutting machine.

Elements of a Fiber Laser Cutter Machine

- Laser beam

It makes it possible for the user to cut the metal into different shapes that they need.

- Mirror

The mirror is used to direct the laser light into focus on the work zone. It should always be kept clean and safe.

- Gas flows

Gas flow is used to remove the molten material when the work is in process. The most commonly used gas is nitrogen since it does not react with metal as compared to oxygen.

- Focusing lens

It focuses the laser beam onto the point where the cutting takes place.

- Nozzle assembly

This is the point in the metal laser cutting machine where melting takes place.

- Exhaust

This is the most important part for users. The exhaust ensures there is good air to breathe when operating the metal laser cutting machine.

Steps for Using EagleTec CNC Company’s Metal Laser Cutting Machine

When purchasing the metal laser cutting machine from the EagleTec Company, you will be taught how to use it. There is also a guidebook manual that will provide you with a step-by-step process. But before that, let us see how it operates for basic knowledge.

Operating steps

- Understand how the machine is installed

- Align the piece of metal to be cut properly.

- Make sure that the metal is straight so that you can cut something accurately.

- Get the fabricators into the zone.

- Wear protective clothing such as an eye shield, hand gloves, and an overall.

- When the cut is over, the supervisor must check the metal laser cutting machine to see if its fabricator has any leakages.

- Check the cooling system to ensure the metal laser cutting machine is at the right temperature to avoid damage.

- Turn off the machine after you clean it to avoid breaking down when using it next time.

Fiber Laser Cutting Machine features

Fiber laser cutting machines from EagleTec CNC Company have many important characteristics. They have high-class quality. The reviews from past customers of the company who purchased the metal laser cutting machine are positive. The following are the key features of a metal laser cutting machine.

- It has a low cost of use.

Everything viable for a business should be economical and cost-friendly. A metal laser cutting machine is cheaper to use. It does not need you to go and fix it. It is purchased when you have already joined, making it cheap for you. Whenever you get a manufacturer like EagleTec Company, they will offer you a discount.

- Modernized technology

Metal laser cutting machines are decorated with a high level of technology. It is operated automatically using electricity or DC power. The machine also has high technological measurements which fit the steel as per the width.

- Section quality is commendable in cutting.

The metal laser cutting machine can cut even hard metals with quality measurements. You just need to adjust the width of each metal as per your requirements. Metal laser cutting machines from EagleTec Company provide you with high-quality cutting sections.

- High cutting accuracy

The tool that is being cut can be moved in all directions. This ensures that the cutting accuracy is well maintained. It is possible since you are using a CNC system.

- Durability

Once you have the machine laser cutting machine, you will use it for a long time. This is possible, especially when you purchase it from a recognized machine manufacturer such as EagleTec Company.

- No limit to the cutting path

Since it can be moved in all directions, it has no limit to the cutting path. It cuts the metal at a high speed, making sure that the metal can be cut without limit. The work will stop only when you are tired.

The benefits of Using a Metal Laser Cutting Machine

- The cutting process is automated.

- It can be used repeatedly.

- The cutting quality is high.

- Metal laser cutting machines have high-efficiency levels.

Metal Laser Cutting Machine Disadvantages

- It uses high energy and electricity.

- Destructive when not used with protective gear.

CONCLUSION

The basic and extensive knowledge of metal laser cutting machines is with you. The honorable thing you can do is to purchase one. This article has taught you important features to consider while choosing the best metal laser cutting machine for your business. Purchase a metal plate laser cutting machine and a laser tube cutting machine from EagleTec Company. The main reason why many experts recommend EagleTec CNC Company is that it has a quality machine. Ensure that you always maintain the cleanliness of the machines after using them. This will help you reduce the cost of repairs.