The heating and cooling needs of industrial facilities can be challenging. When working indoors, you will need to adjust the temperature of a building to match the outside air.

This process is known as climate control. Climate control is essential for protecting sensitive equipment from damage.

Industrial heat elements help facilities keep their working environments at the desired temperature. You can also use them to heat specific equipment.

What Is a Heating Element?

A heating element is a solid surface that emits Óradiant heat. It does this by converting electricity into heat in equipment that heats or cools a space. These can be surface-mounted, embedded, or suspended in the air. Some heating elements pass electricity through metal wires exposed to air or embedded.

As electricity flows through these wires, they heat up to produce radiant heat. These elements are also sometimes called induction heating elements. Induction heating is the transfer of electricity through metal coils. Heating elements ensure consistent temperatures inside of a structure or around a machine.

What Is Heating in the Industrial Sector?

Industries like refineries and chemical plants use heat as a primary energy source. Industrial heat elements play an essential role in maintaining and processing temperature.

A heating element is a versatile solution for managing indoor temperatures or equipment. It might come as a heating panel that can produce any desired temperature. It does this thanks to its built-in microcontroller and sensors.

Types of Heating Elements

These days, there are many different types of industrial heat elements. You can use these heating elements for heating, cooling, or both. Some elements are designed for one purpose, while others adapt for either of them.

-

Flexible Heater

The flexible type of heater is one of the best choices for businesses. Custom flexible heater are a necessity for many companies. There are various kinds of flexible heaters. They include silicone rubber heaters, Kapton heaters, and polyester heaters. Kapton heaters are also polyimide heaters.

Flexible heaters are heaters that you can bend or fold to fit a non-uniform surface. You can apply a flexible silicone heater directly where you want it. Flexible heaters help to prevent overheating in mobile phones. They also help to regulate the temperature in life-saving equipment.

-

Convection Heater

Convection heating elements are like a standard electric heater. When you apply a voltage, the element draws heat from its surroundings. It then radiates it in the form of infrared waves. These waves can pass through most objects and transfer their energy to the area.

-

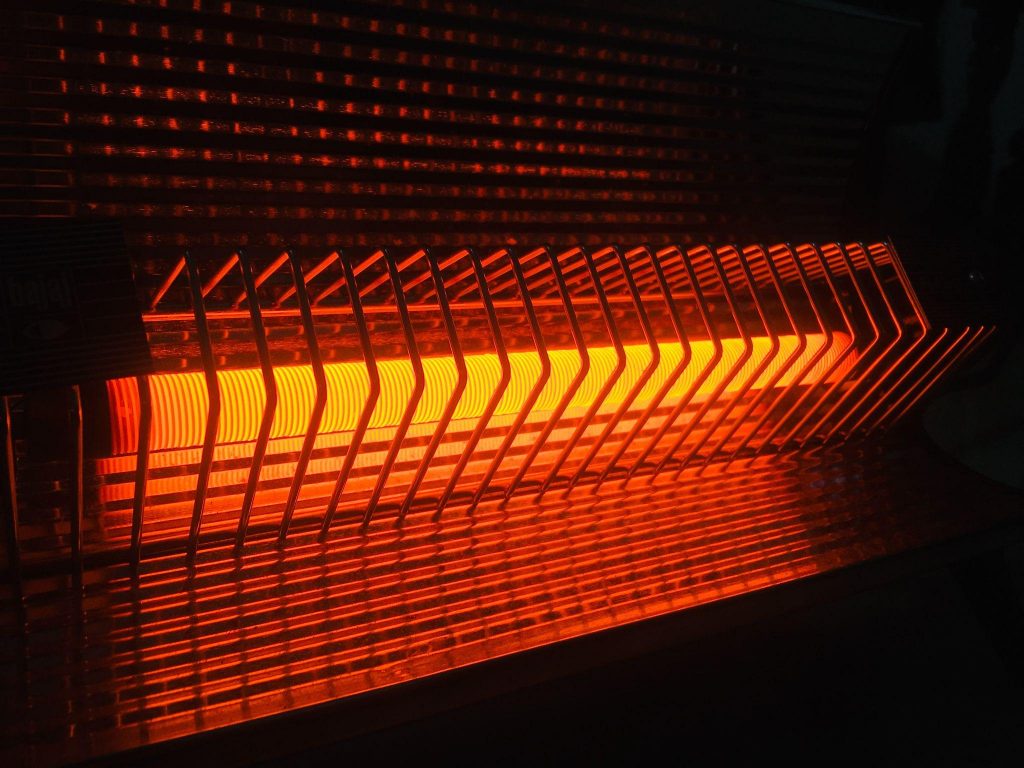

Infrared Heater

Infrared heating elements generate heat by emitting invisible infrared rays. The objects absorb the rays and convert them into heat energy. They are very efficient and can heat up a big space.

-

Radiant Heater

Radiant heating elements rely on visible light rays to transfer their energy. This makes them very efficient. However, their distance is shorter than that of infrared or convection heating elements.

Why Does the Industrial Sector Need Heating Elements?

Heating elements are useful for indoor spaces that need consistent temperatures. The elements maintain a set temperature, even when the outside temperature varies.

Industries that use heating elements include food and beverage, pharmaceutical, healthcare, and transportation. These heat industries enjoy consistent indoor temperature regulation.

From the heat produced by electricity to the impact of humidity, it can cause severe damage to sensitive equipment. Heating elements protect equipment from damage. They also create a healthy workspace while reducing the amount of electricity they need to operate.

Benefits of Heating Elements

-

Protects Sensitive Equipment From Damage

Heat protects equipment from short circuits and overloading. In addition, it will help to keep sensitive equipment at a consistent temperature. It also prevents damage caused by too much humidity or too low temperatures.

Mold and mildew often become problems when a building’s temperature is inconsistent. Controlling indoor temperatures can help protect against them.

-

Extremely Reliable

Industrial heating elements are designed to withstand the demanding conditions in a facility. These elements can withstand high temperatures, extreme weather conditions, and frequent equipment actions.

-

Makes Working in Cool Temperatures Easier

Keeping working environments at a desirable temperature has many benefits. As a result, employees will be able to complete more work. An ideal temperature can help prevent fatigue due to excessive heat or cold.

A room’s temperature can affect a person’s concentration and performance. Hot temperatures can affect people negatively. Likewise, cold temperatures can make it hard for them to work. So, companies situated in naturally cold environments can use heaters to equalize temperatures in working conditions.

-

Can Easily Be Replaced

Another great advantage of using heating elements is that they can easily be replaced. This is because you don’t have to change the wiring or plumbing system when you change the heating elements of a machine or appliance. Instead, you only need to replace the old ones with new ones.

As a result, this might save you time and money. However, do not attempt to install or replace some of the heating elements yourself if you have no experience. Some of them will require professional assistance.

-

Protects Against Health Risks

Working in low temperatures can lead to bad moods and health risks. Some of these risks include respiratory problems and dizziness.

Some heating elements regulate the overall temperature of the room for optimum performance. This way, efficient heating elements will help reduce the risk of injury for employees.

-

Heating Elements Are Compact

Some heating elements, like induction and electric heaters, are compact. These heating elements are most popular in the food and beverage, pharmaceutical, and chemical processing industries.

Other than these industries, you can also find flexible heating elements in credit card scanners, toasters, hairdryers, security equipment, and food service equipment. Also, since they are compact, they are easy to install in a substance or a material.

-

Environment-Friendly

Heating elements emit no toxic fumes, so they are considered environment-friendly elements. They are also less disruptive because they produce less noise than other heating devices. Another great environment-friendly feature of these elements is that they are often maintenance-free.

Thus, heating elements are easier to keep in good condition when it comes to maintenance. They don’t require any special care or maintenance, so they are hassle-free. As a result, they are good environment-friendly elements in the industrial sector.

-

Long Lifespan

Heating elements are durable and can last for a very long time. First, however, ensure that you install them properly. Some of these heating elements are installed in grounded electric outlets. As a result, you do not need to take care of them.

As for other heating elements, they are installed in various appliances, ducts, or flues. Therefore, duct and flue cleaning is required from time to time. These cleaning processes remove the dust and debris in the ducts and flues and make the heating elements last for a more extended time.

-

Easy to Operate

It is easy to use some electric heating elements to get the right temperature at the right time. They are also easy to install and take down. For example, to use an electric space heater, all you have to do is plug it into a wall socket and turn it on.

The electric heater comes on and heats up almost immediately. To uninstall, turn the switch off and unplug it from the wall. Make sure it cools down before moving it.

Conclusion

There are many benefits to having industrial heating elements in place, especially if you work in an industry that requires consistent temperature. They can help protect against damaging changes in temperature and reduce energy consumption.

They also maintain a set temperature for equipment inside a building. Even when the outside temperature varies, the case remains so.