3 Ways through Which IoT Transforms the Modern-Day Businesses

We can see that IoT (Internet of Things) adoption is largely gaining momentum in various sectors ranging from home automation to industrial processing. Experts confirm that this is one of the key technologies which will shake up the business world in the future. Everything we do and every business activity we engage with generate data. Smartwatches that we wear tend to track each step, heart rate, location, and distance covered, etc., in real-time. The smartphone we don’t know nowadays knows everything about where we are, what we do, what we buy, where we go on a holiday, and what you are thinking of buying next!

Going forward, we are doing to live in an Internet of Things (IoT) based world, which will impact our day-to-day lives and benefit everyone. It will not only keep us connected but also can bring forth the most important things to us. When it comes to the usage of IoT in the business sector, it is no different. The IoT devices will record data and transfer it for various processes. Data can be effectively used to gain insights, boost process efficiency, and let key decision-makers make well-informed data-driven decisions. Most of these insights will act to the advantage of the consumer itself and also the product marketers.

IoT-based data from various data points can tell the organization as to what is happening than making assumptions. The data that they gather also feeds the analytics and artificial intelligence systems, which can easily identify the patterns of user behavior that were not clear before. IoT markets include hardware, software, telecom services, integrations, and more. Now, more and more companies are running their proof of concept in Ai and IoT-based projects. Also, there are many new enterprises considering exploring various use cases.

Suppose you are exploring how IoT technology can be leveraged in your enterprise for expediting growth. In that case, it is important to understand some of the key transformational strategies related to this technology. Let’s discuss.

-

Improve customer experience

Nowadays, connected equipment in aviation, supply chain, manufacturing, healthcare, agriculture, and many other industries helps create greater insights into business operations and how the customers tend to use their services. It may be enabled through cloud platforms like AWS, Microsoft Azure, Google, IBM, and many other vendors in many such instances. However, this fundamental shift is now sailing towards edge computing in many industries, which comes with an effort to reduce the overall latency by relying largely on remote data centers. When an enterprise realizes how their customers use the products, they can easily cater better to the user needs for improved customers experience and acceptance of their products.

In various ways, the retail industry is now at the forefront of such technology-driven changes. This comes with the need to change, reflected in a widely reported fall of various traditional brands. In the meantime, providers like Amazon and Ocado had thrived on their data-driven strategies. We can see that the future of retail now largely relies on connecting better with the customers and reducing friction. For IoT-based application database services, avail support of RemoteDBA.com experts.

-

Reduction of cost and downtime

Another major use of IoT-based technologies is better insights with a reduction in operational expenditure and lesser downtime. Say, for example, the emergence of digital twin technology. With this, you can make digital models of the physical assets by feeding real-time data. It can either be in pure data form or as some 3D representations. In combination with other technologies like big data, AI, smarter supply chains, machine learning, augmented reality, etc., digital twin programs now promise unique predictive and proactive maintenance opportunities

Now, consider a setup where each part of this installation is represented with a digital twin, which can predict to the engineers which component will fail days in advance and what to do about it! You can see how the failure of a single but critical component in the industrial installation causes many days or weeks of downtime, while there is a possibility that this fault can be traced in seconds and fixes. As a result, a brief maintenance schedule to replace the component can save millions of dollars and ensure zero downtime, which otherwise may have impacted the process adversely.

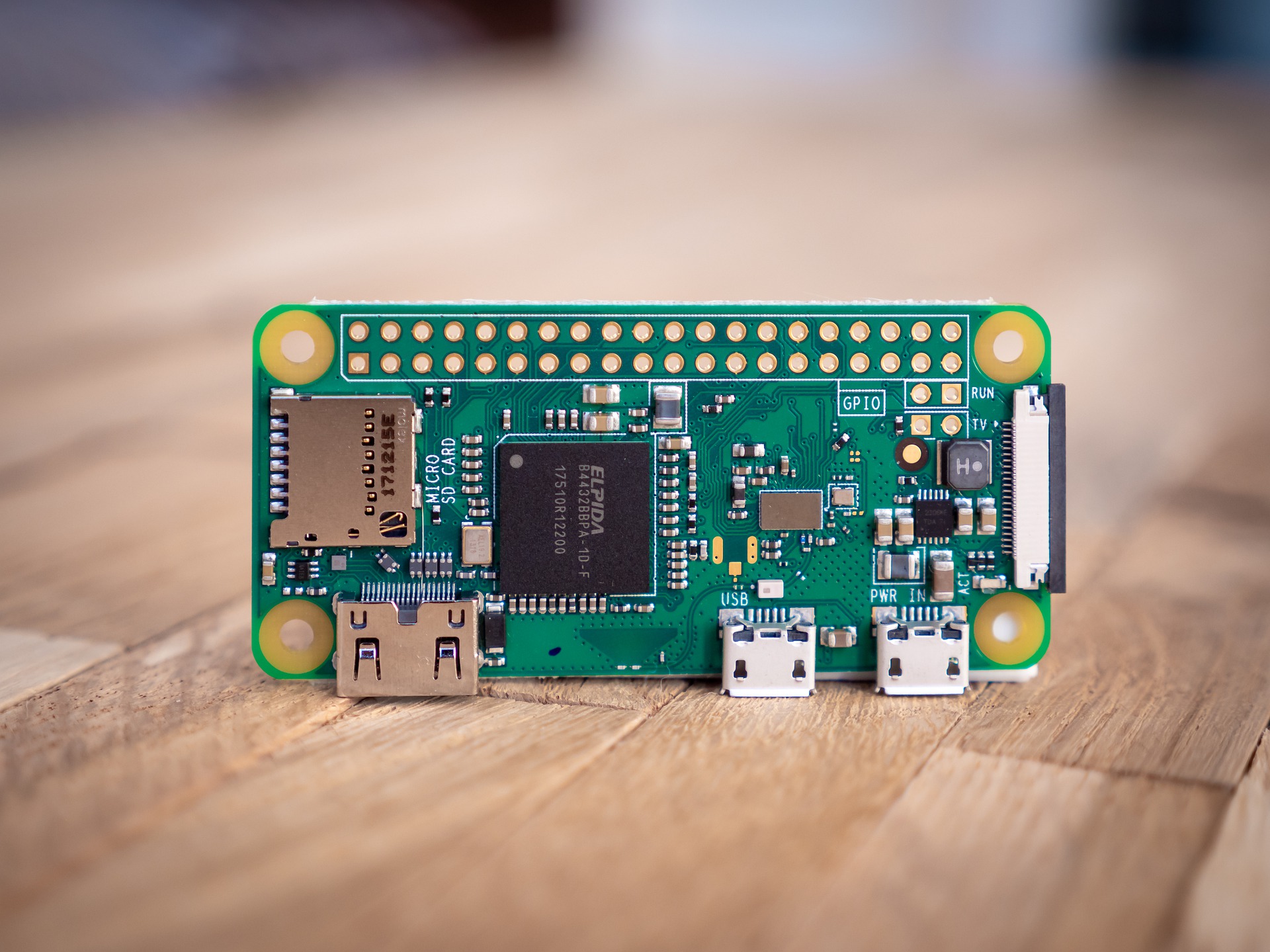

Here, IoT-based technologies can help cut down both operational costs and downtime in manufacturing and other industrial settings. These will also help the workers learn their job and how the machines work and pre-schedule the upgrades and maintenance. This can be monitored through smartphones, tablets, AR devices, smart goggles, etc.

In a real-time example of the same, you can see how Laing O’Rourke, as a leading construction services provider, users digital twin technology to solve the problems that many competitors face in their daily lives. Laing O’ Rourke has set forth a class example of how construction firms can use and optimize the digital twin platform to reword their operational flow.

-

Ensuring productivity and efficiency enhancement

IoT can be used to connect the key business processes, with which the leaders can easily identify the ways to boost their productivity and efficiency. You can see Ford’s Valencia Engine Assembly Plant Ford, where the employees use a modern suite equipped with body-tracking technology.

This technology is similar to any other motion-tracking, which records how the athletes sprint on their events or how the actors move in the field. Ford uses the same technology to reduce the physical stress at the workstations and improve the efficiency of their manufacturing process. By tracking workers’ movements accurately, Ford enables data-driven changes to its automobile production to make it more efficient and safer. This same principle is also applied to their machines to understand the bottlenecks in the production line, however small it is.

Some other uses of IoT in industrial settings are wastage reduction, asset tracking, building new business models, etc. When combined with other relevant technologies like AR, AI, VR, big data, robotics, and blockchain, a business using IoT can unlock its untapped revenue and gain a competitive advantage over its competitors.